|

We support sputtering targets for all fields including TFT, OLED (LTPS: Low-Temperature PolySilicon) and touch panels.

|

|

Ultrasonic defect testers ensure meticulous quality assurance. ULVAC has installed large ultrasonic test equipment to make meticulous defect inspections of materials and bonding inspections. Using this equipment has helped ULVAC drastically cut down on arcing during sputtering and deliver high-quality targets.

|

|

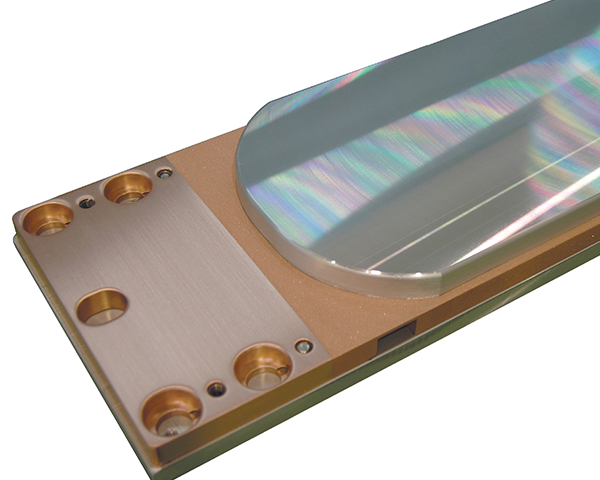

High-reliability metal bonding technology

Large sputtering targets are very heavy so the technology for bonding to a cooling plate (backing plate) is extremely important. ULVAC has installed bonding equipment to support the deposition of larger glass substrates and realized an all-inclusive target supply system.

|

|

Low-particle targets.

|

|

Attaining high uniformity by adjusting the metal microstructure.

|

Cu-Mg-Al Alloy for Low-Resistance Copper Wiring

|

|

The ideal target for deposition forming in low-resistance wiring processes. (Stacking structure uses Cu-Mg-Al alloy as an adhesion layer for a pure copper film).

|

|

Good adhesion to glass substrates, oxide layers (ITO, etc.) and silicon system under layers (SiO2).

|

|

Wet etch processing is easy because the copper material is similar to the wiring layer material. (Processing can also use an etching solution (single fluid) not containing hydrogen peroxide or fluoric acid.)

|

|

Low-cost process.

|

|

Inexpensive target material.

|

| |

|

|