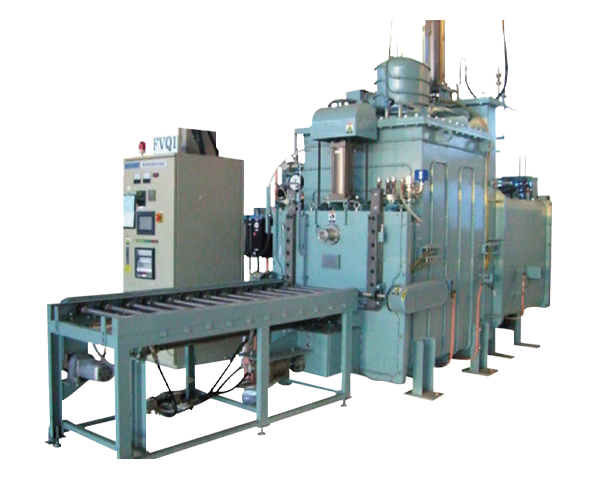

Horizontal Type

Vacuum Heat Treatment Furnace

FHH Series

FHH series are used for various purposes such as quenching, tempering, sintering and brazing of various metals.

Chamber configuration can be multiplied up to 3 chambers by adopting a fork carry system.