These VS series pumps are typically used in a wide range of applications, especially those having a large number of repetitive pumping steps that cycle from atmospheric pressure, such as in the automated leak testing of parts, as well as numerous other industrial applications.

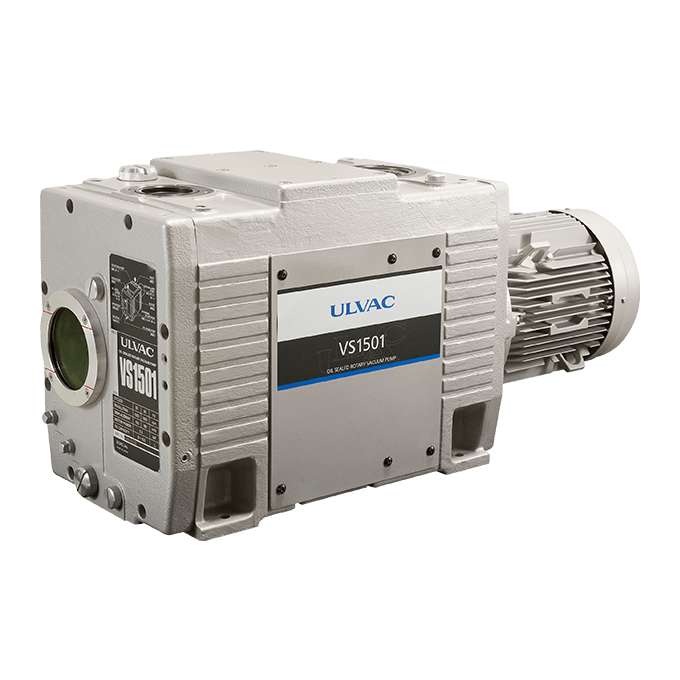

The VS650A and VS750A are single stage oil rotary vane pumps. Designed to provide low vibration and noise, the VS series eliminates the need for costly facility work. Both air-cooled and water-cooled models are available depending on customer installation requirements.

Features

|

Low vibrations and noise.

|

|

Lightweight, compact.

|

|

Enable continuous operation at full pressure.

|

|

Outstanding ease of maintenance.

|

VS650A VS750A

|

|

High displacement single stage oil rotary vane pump :

Two models, 650m3/h and 750m3/h are available. Larger displacement can be obtained with the combination of mechanical booster pump.

|

|

Designed to provide low vibration and noise, the VS series eliminates the need for costly facility work. The pump can be installed on an upper floor.

|

|

Oil exchange cycle is longer due to a large oil tank (large oil capacity).

Construction of an oil tank is simple and easy to clean.

|

|

Oil mist trap is inside the oil tank. Cartridge type filter is easily replaced.

|

|

Air-cooled and water-cooled models are available depending on customer installation requirements. An oil cooler is used to reduce oil temperature increasing pump life.

|

| | | |

Applications

|

Evaporation, sputtering, ion plating.

|

|

Vacuum packaging, vacuum adhesion, transport.

|

|

Vacuum heat treatment furnaces, sintering furnaces, brazing furnaces, brazing.

|

|

Vacuum drying, freeze-drying, vacuum degassing.

|

|

Gas exchange/supply, vacuum insulation.

|

|

Automated leak testing, etc.

|

| |

|

|