|

The electron beam is deflected by the electromagnetic field and the effect of secondary electrons on the deposition target is extremely small.

|

|

Scanning the beam spot in the X-axis and Y-axis directions even with a sublimable substance can eliminate the partial digging phenomenon and the entire crucible can be evaporated smoothly. (Japan patents 831485, 843447).

|

|

The electron beam is deflected 270°, so it is not exposed to the above from the vaporized material and the filament has a long life.

|

|

Since the emitter assembly can be easily attached and detached, it is easy to replace the filament, insulator, etc.

|

EGL-35

|

|

Large-capacity vapor deposition is possible by using a large-capacity 40cc hearth.

|

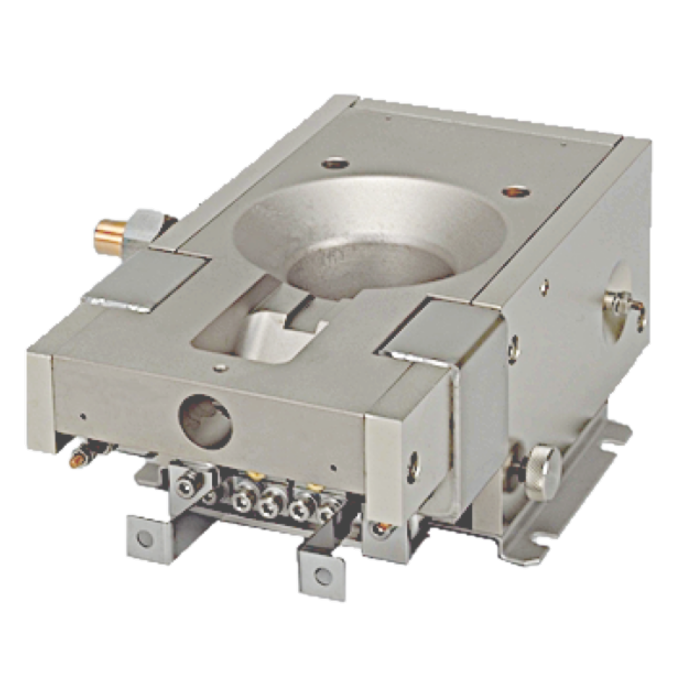

EGL-35M

|

|

Multi-layer film deposition is possible by adopting a 4-point switching hearth with a capacity of 40cc and 10cc.

|

|

The hearth position detection mechanism is installed as an option and hearth rotation can be automated.

|

EGL-80M

|

|

Large-capacity multi-layer deposition is possible by adopting a large capacity 110cc 4-point switching hearth.

|

|

Adopting a water-cooled magnet coil allows continuous operation in high temperature atmosphere.

|

|

The hearth position detection mechanism is installed as an option and hearth rotation can be automated.

|

EGL-103S

|

|

Suitable for small-scale production in ultra-high vacuum due to the adoption of a direct-acting 3-point switching hearth with a capacity of 10cc.

|

EGL-110

|

|

Large-capacity vapor deposition is possible by adopting a large capacity 110cc hearth.

|

| |

|

|